A biological safety cabinet (BSC) is an engineering control intended to protect laboratory workers, the laboratory environment, and work materials from exposure to infectious or biohazardous aerosols and splashes. Such aerosols and splashes may be generated while manipulating materials containing infectious agents, such as primary cultures, stocks, and diagnostic specimens.

There are three kinds of safety cabinets, Classes I, II, and III. Class II and Class III biological safety cabinets provide personnel, environmentalas well as product protection. Whereas the class I safety cabinet, which is the most basic one, provides personnel and environmental protection only. When properly used Biological safety cabinets have been shown to be highly effective in reducing laboratory-acquired infections and cross-contaminations of cultures.

Safety cabinets have to be certified periodically for their efficiency. Various field tests are performed to verify air flows, HEPA filter integrity, containment of contaminated cabinet air etc.

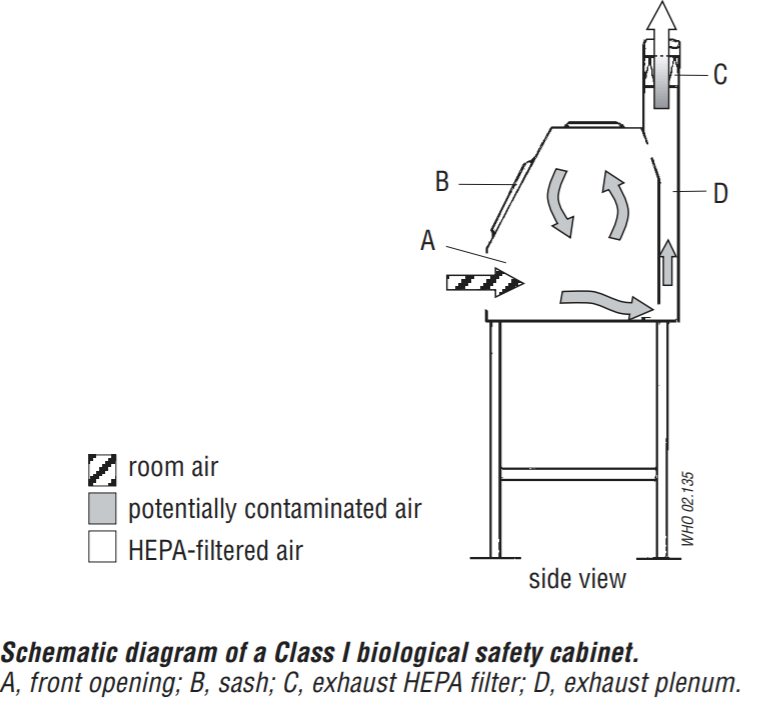

Class I Biological safety cabinet

Class I BSC is the first designed and simple Biological Safety Cabinet (BSC) which provides personnel and environmental protection but not product production (as unsterilized room air is drawn over the work surface). Class I BSCs are suitable for work with Risk Group 1 (RG1), Risk Group 2 (RG2), and Risk Group 3 (RG3) biological material.

Working mechanism

Room air is drawn in through the front opening at a minimum velocity of 0.38 m/s. The front opening also allows the operator’s arms to reach the work surface inside the cabinet while he or she observes the work surface through a glass window. The window can also be fully raised to provide access to the work surface for cleaning or other purposes.

The directional flow of air whisks aerosol particles that may be generated on the work surface away from the laboratory worker and are then discharged from the BSC through a HEPA filter.

HEPA filter traps 99.9% of particles of ≥ 0.3 µm in diameter. This enables the HEPA filter to effectively trap all known infectious agents and ensure that only microbe-free exhaust air is discharged from the cabinet and/or recirculated in the work surface.

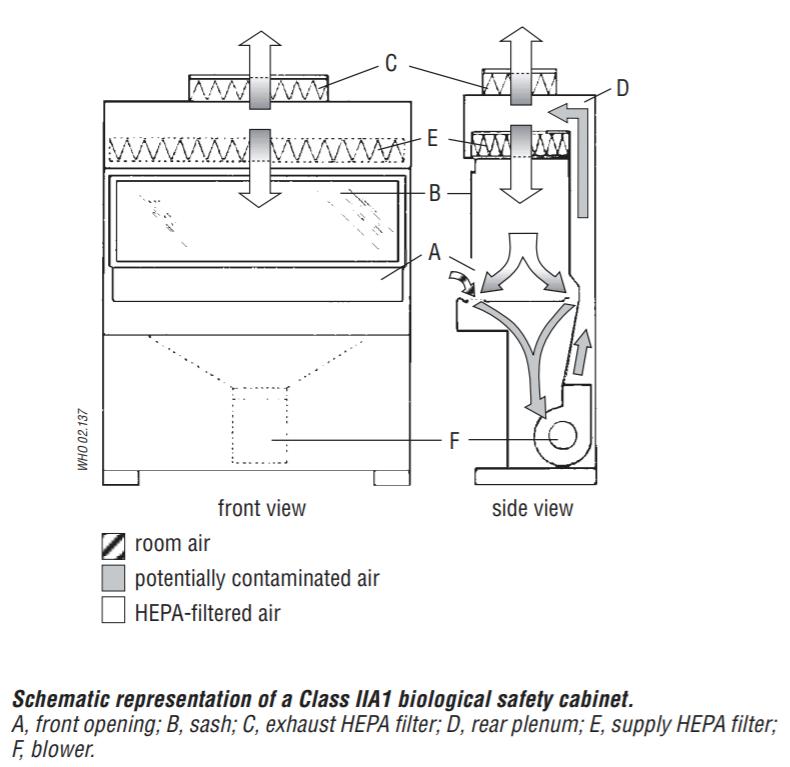

Class II Biological Safety Cabinet (BSC)

A Class II Biological Safety Cabinet (BSC) is a ventilated cabinet, which provides personnel, product, and environmental protection. It is commonly found in clinical and research laboratories working with infectious agents in Risk Groups 2, 3, and 4 (if positive-pressure suits are used) or with tissue culture.

There are four types (A1, A2, B1, and B2 ) of Class II BSCs. The main differences between the types are the ratio of air exhausted from the BSC to the air that is recirculated within the BSC, and the type of exhaust system present.

About 90% of all biosafety cabinets installed are Type A2 cabinets. There is a limited need for Class II Type B biological safety cabinets. In addition, Class II Type B biological safety cabinets require very specific installation and operating conditions to function correctly.

Working Mechanism

The working mechanism of Class II BSCs differs according to their types. It has an open front with inward airflow for personnel protection, downward HEPA filtered laminar airflowover the work surface for product protection and HEPA filtered exhausted air for environmental protection. The room air and recirculated air are HEPA filtered before flowing downwards over the work area. Class II BSCs can be exhausted into the containment zone or directly to the outside atmosphere through a thimble or hard-ducted connection depending on the type. The amount of air that recirculates or exhausts depends on the type.

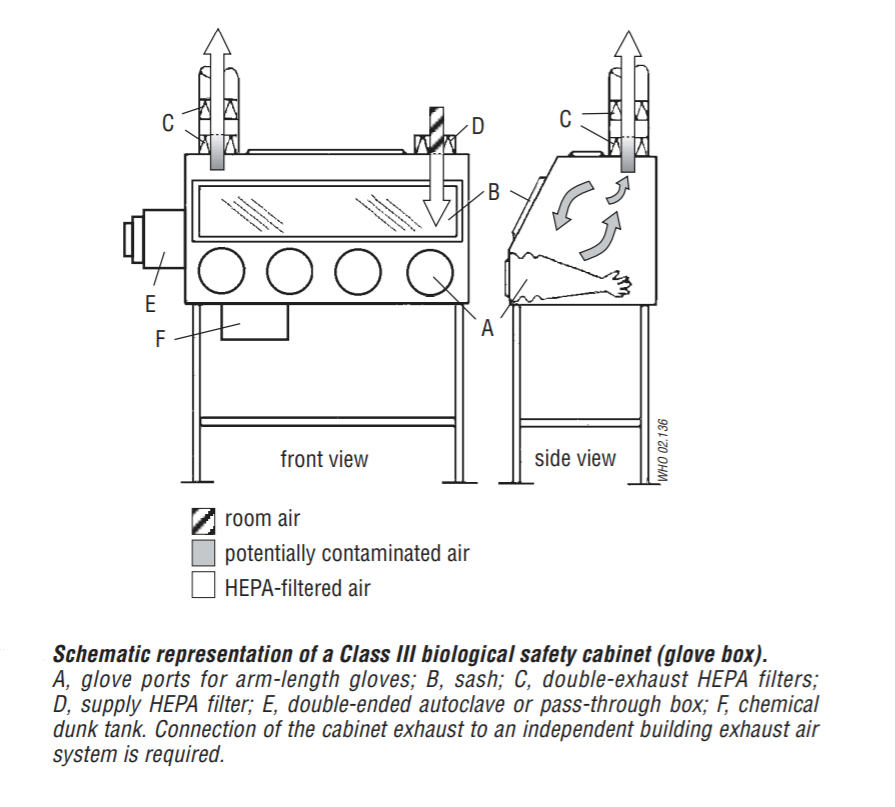

Class III Biological Safety Cabinet (BSC)

Class III BSC provides the highest level of personnel protection and is used for Risk Group 4 agents. It is suitable for work in Biosafety Level 3 and 4 laboratories.

Working Mechanism

This type of cabinet is totally enclosed and is tested under pressure to ensure that no particles can leak from it into the room. Supply air is HEPA-filtered and exhaust air is discharged into the atmosphere through two HEPA filters. The operator access the work surface by means of heavy-duty rubber gloves which form part of the cabinet. Several glove boxes can be joined together to extend the work surface. Airflow is maintained by a dedicated exhaust system exterior to the cabinet, which keeps the cabinet interior under negative pressure.

The Class III BSCs should have an attached pass-through box that is sterilizable and equipped with HEPA-filtered exhaust. The Class III cabinet may be connected to a double-door autoclave used to decontaminate all materials entering or exiting the cabinet.

Features of Class I, II, and III BSCs

References and further reading

| Type | Face velocity (m/s) | Airflow (recirculated) | Airflow (exhausted) | Exhaust System |

|---|---|---|---|---|

| Class I | 0.36 | 0 | 100 | Hard duct |

| Class IIA1 | 0.38-0.51 | 70 | 30 | Exhaust to room or thimble connection |

| Class IIA2 | 0.51 | 70 | 30 | Exhaust to room or thimble connection |

| Class IIB1 | 0.51 | 30 | 70 | Hard duct |

| Class IIB2 (Total Exhaust BSC) | 0.51 | 0 | 100 | Hard duct |

| Class III | NA | 0 | 100 | Hard duct |

- Laboratory biosafety manual, Third edition, World Health Organization (WHO), 2004.

- A Guide to Biosafety & Biological Safety Cabinets. ESCD.

- Richmond JY, McKinney RW. Primary containment for biohazards: selection, installation and use of biological safety cabinets, 2nd ed. Washington, DC, U.S. Department of Health and Human Services/Centers for Disease Control and Prevention/National Institutes of Health, 2000.

- Health Canada. Laboratory biosafety manual, 2nd ed. Ottawa, Minister of Supply and Services Canada, 1996.

- Massachusetts Institute of Technology, Environment, Health & Safety Office, Biosafety Cabinets.